Benchmarking has become a major part of running a business today. Whether it’s comparing this year’s performance to past performance or looking at your profitability compared to similar operations in your region or province, it’s considered an essential tool for setting production goals.

But finding the best benchmarks can be tricky. There are hundreds of ways to run a cow-calf operation, and some practices that might work in one area may not be a fit for another. To date, cost of production (COP) analysis for the sector has been confined to provincial or regional data with each project using a different method of calculating and defining costs.

The new Canadian Cow-Calf Cost of Production Network — which recently released its 2020 report — intends to break that trend, providing cow-calf producers with benchmarks based on standardized, nationwide methodology. Its goal is to break Canada’s cow-calf COP practices down into smaller producer demographics, allowing producers to find the benchmarks which best apply to them.

“By using a standardized methodology, the information will be interpreted the same in each province. So hopefully it will reduce the confusion caused by one producer talking about benchmarks in their province to another when actually the methodologies were different,” says Brenna Grant, manager of CanFax Research Services, a division of the Canadian Cattlemen’s Association.

The COP network fills an important gap in Canadian cow-calf cost of production benchmarking, she says.

“There have been a lot of funding cuts to provincial programs that have offered a cost of production over the past several years. This will be the first time that cost of production information will be available for every province, with data collected from British Columbia to Prince Edward Island. We really wanted to fill that gap where some provinces haven’t had COP data for several years now.”

One thing that’s unique about the COP Network’s approach to collecting data is that participating producers actually see each other and are encouraged to share solutions with their focus group partners. Grant calls it “learning in community.”

“I saw a couple of different farms that had challenges with predators and so a number of them had higher calf death loss. We paused and everyone got to share what they were doing for predator control, the pros and cons of what they were doing and would they do it again that way.

“It’s more than just benchmarking. We want to encourage innovation and pass on knowledge through these networks and connections being made.”

More grazing equals less COP

The COP network recently released its report on last year’s growing season. The 2020 network comprises 25 cow-calf operations, three dairy/beef production systems and 115 individual participants from across Canada measuring their animal performance traits, economies of scale, labour productivity, feeding systems and financials.

Winter feed systems and costs were two of the many factors studied among the 25 operations. Total winter feeding days ranged between 150 and 250.

Although not reflected in the 2020 data, the hot, dry conditions which sucked the life out of pastures this past summer carries the potential need for cow-calf producers to expand their winter-feeding days this year, says Grant.

“The biggest impact of 2021 is from the potential need to increase winter feeding days. Grass management is really key this year,” she says.

“The farms with 100 per cent purchased feed were hit the hardest this year with increased market prices.”

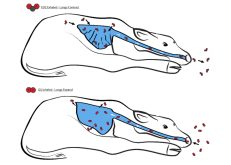

In the 2020 study, feed costs averaged about 40 per cent of total production costs (including cash, depreciation and opportunity costs) in the network. A 2020 study by the University of Saskatchewan found that swath grazing was the lowest-cost method, with forage costing $1.43 per head per day compared to drylot greenfeed forage at $1.75/head/day.

Using the COP for homegrown feed and market value for feed purchases divided by feeding days resulted in a network low of $1.20/head/day on a cow-calf operation in Alberta to a high of $3.94/head/day in central B.C. The national COP average for winter feeding was $2.30/head/day.

In short, the more grazing an operation did, the lower its cost of production. The study found that production systems with feed costs of less than $1.50/head/day used swath grazing followed by a mix of silage and hay.

All the production systems with feed costs of less than $2/head/day purchased 20 per cent of their feed or less. One operation in Quebec was unique in that it achieved $1.50/head/day feed costs using only home-produced hay alongside purchased minerals and salt.

In a nutshell, the producers with the lowest winter feed cost used extensive feeding, with many using annual crops, hay and silage as their feedstuffs.

‘Right-sizing’ your operation

The Alberta operations’ relatively low winter feeding COP was due largely to its use of swath grazing, a widespread practice in Alberta thanks to an appropriate climate and about two decades of extension outreach that has helped beef producers learn the practice.

Does that mean cow-calf producers across the country should drop everything and adopt swath grazing? Although it may make sense on paper, in reality it may not always be realistic, says Grant.

“Sometimes you can get this idea that hay is expensive and swath grazing is cheap and all these different things. An operation can be high- or low-cost with any feedstuff,” she says.

Rather than switch modes of feeding, a more profitable idea might be to “right-size” — or optimize — your operation, says Grant, starting with the size of your cows.

“The cost of feeding an 1,100-pound cow is going to be different than feeding a 1,500-pound cow in terms of just volume.”

The second factor to look at is economies of scale. “Most of the farms in the network at this point are — at less than 300 head — still fairly small. However, we saw that the larger operations at around 250 head had significant economies of scale advantages that really drive down some of those winter feeding costs.”

Some of the operations with the highest cost of winter feeding were the smallest. “Those farms from B.C. and the Maritimes were actually some of our smallest farms that simply did not have the economies of scale.”

So why are economies of scale so important to COP? It comes down to stretching your resources over your herd, says Grant.

“If a farm has 30 head and has as many acres as you need to develop your feed, whether it’s 100 per cent hay rations or something else, you still need a tractor and a baler and a swather.

“In contrast, a 200-head operation still needs a tractor, a swather and a baler but it’s being spread across more acres and across more cows. On a mixed operation with grain, that tractor — in terms of depreciation and machinery repair — is being spread between your grain operation and your cattle operation.

“A lot of these small cow-calf operations tend to have just 20 or 30 head and depend on off-farm income. There’s nothing wrong with that. It’s the fact that they then have higher cost structures because that tractor is 100 per cent allocated to the cow-calf enterprise and it’s going on fewer acres and being spread across fewer cows.”

Larger operations needed

The 2020 report is just the beginning. The COP network is currently looking for participants in next year’s data collection, which will take place between January and March 2022.

“We’re looking to expand the types of cow-calf operations represented in the network and to validate the existing production systems with the producers,” says Grant. Further information is available online or by calling CanFax at (403) 275-5110.

“Over the next two years, we’re going to be doubling the number of benchmark farms. The goal is to have a large enough sample size to be able to create provincial benchmarks that are representative of all the different production systems within a province.”

Although the network is looking for a range of cow-calf operations, it’s in particular need of input from larger producers who run 500 or more head.

“We are definitely looking for larger operations,” she says. “It’s really to understand the whole scope of different production systems and the drivers to profitability behind them.”