According to the 2017 Western Canadian Cow-Calf Survey completed by the University of Saskatchewan, 3.1 per cent of the overall 5.4 per cent calf death loss total occurred at birth or within 24 hours.

To help reduce these numbers, calving management and practices are constantly adapting with technology, artificial intelligence, machine learning and the Internet of Things (IoT) moving parallel to producer inventions, basic tools and equipment.

Moocall calving sensor

Read Also

Treaty Land Sharing Network expands reach in Saskatchewan and Alberta

The Treaty Land Sharing Network, which connects land holders with First Nations and Metis people, has expanded since it began in 2018

Moocall, a farmer-founded, Ireland-based developer of smart products, began offering an intuitive, easy-to-use, tail-mounted calving sensor in 2015.

The sensor is charged for four to five hours before use, then simply turned on by pressing the power button. A full battery charge lasts up to 30 days.

An initial readiness test is completed and confirmed via text message. Attaching the non-invasive sensor is done by securing it to the animal’s tail with non-slip rubber strips placed opposite the vulva and pulling the strap tight.

“The sensor works with an accelerometer, which means it reads a cow’s specific tail movements that only occur when in labour,” says Cindy Giao, Moocall’s marketing director. “Our Breed Manager app allows you to have the herd in the palm of the hand — plus if linked to the Moocall calving sensor, you’ll also get an alert on the app when the cow starts to calve.”

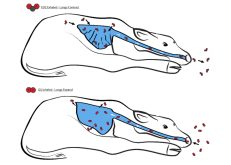

The sensor works by detecting a cow’s contractions by identifying unique tail movements. An algorithm recognizes this by filtering out normal movements and determining the length and intensity of the contractions. Up to 600 pieces of data are gathered every second.

[RELATED] VIDEO: Artificial intelligence at the heart of cattle ID system

When the desired threshold is reached about two hours before calving, the system sends a text message to as many as two different phone numbers, an email address or Breed Master mobile app notification. A second alert is given approximately one hour before calving.

“Since the Moocall calving sensor is not an invasive device, it’s simple to move it from a cow that has calved to another nearing labour,” Giao says. “Just open the ratchet, release the strap, press the button for a second and it’s ready to use it on another cow.”

Cows are assigned the sensor by selecting their identification, the calving sensor number and updating their profile on the ‘In-Calf’ section of the app.

Moocall calving sensors have proven to be up to 95 per cent accurate and can be purchased through the website, by phone or online. They’re available throughout North America with the updated, newest 4G units arriving in January 2023. The cost of a single Moocall calving sensor is approximately $330 and the unit comes with a charger, 24 months of data, software, updates, warranty and support.

The calving assist

Help often comes in the form of a simple piece of equipment designed to make calving easier and safer for both the animal and the handler.

When dairy farmer Jim Ryan of Cashel, Ireland, experienced ongoing back issues, he designed a belt and harness system he called the ‘calving assist’ to help deliver calves without straining his back.

“After I realized I had lost power in my lower back, I came up with the calving assist,” says Ryan. “Sometimes, cows will go down against a wall or be in tight quarters, or they just need a little help, and you have to pull the calf. There’s no other choice.”

The wide belt fits around the glutes, protecting the lower back and the shoulders while the wearer takes advantage of leg power and body weight during pulling. Ropes or chains are attached to two metal grapples to securely hold the harness, ropes and calf.

“A strap helps secure the belt around the waist,” says Gerard Browne, online marketing executive for FRS Direct. “For safety, when the animal isn’t restrained and moves off quickly, one of the stainless-steel handles has a lever for a quick release disconnecting the harness away from the animal to prevent any injury.”

The device is marketed by FRS Direct, an agricultural equipment supplier based in Ireland. While it isn’t readily available through dealerships in North America, it can be ordered for oversea delivery.

Computer vision

As help is often required during calving, knowing when to step in is critical. To help identify this time more accurately, Mediaan, a data-driven tech innovation company, is using computer vision to analyze animal behaviour and health.

Unusual behaviour often indicates trouble or unusual circumstances. Mediaan’s technologies use visual imaging data and create smart algorithms based on this information. Artificial intelligence allows customers to apply it in day-to-day operations.

The company’s camera and computer vision techniques use object detection to recognize the signs of upcoming labour such as loss of appetite, restlessness, or continuous lying down and rising. Farmers check video feeds from their phones. The system will also send an alert when unusual (birthing) activity requires attention.

While the system is still in its early stages, technology is advancing rapidly. Detection models are being trained to find the correct patterns used to identify and locate objects. Network algorithms such as ‘You Only Look Once’ (YOLO) are accessing more and more data to become increasingly defined and accurate. Computer vision testing is constantly ongoing.

Cows delivering calves will be a constant in farming’s future. Technology will likely play an even larger role in this natural process, but at times it will still be helped by simpler and more straightforward innovations.

Bruce Derksen lives, works and writes in Lacombe, Alta. He has 30 years of experience as a hands-on participant in numerous branches of the Western Canadian livestock industry.