The majority of cattle feeding in Western Canada has been centered in Alberta. But since the early ’70s, an operation in Saskatchewan has stood out. The corporate vision statement of “Leadership in sustainable, innovative agriculture” of Pound-Maker Feedlot at Lanigan, Sask., illustrates the company’s unique approach with the synergies of Canada’s first livestock feeding operation and ethanol plant. One of the original motives of a group of 50 local farmers was as a grain marketing venue with a 2,500-head lot. The ethanol plant was added in the early ’90s and the feedlot expanded.

Read Also

Building demand together: The impact of Canada’s beef import levy

The beef import levy has become a central tool for ensuring balance in Canada’s beef industry

The initial local group of mostly local shareholders has grown to over 200. The companies are governed by a board of eight members, which are elected by the shareholders. Brad Welter is the current president and has been for five years, following the leadership of Brad Wildemen, who still sits as a board member. Wildeman is well-known as a leader in the Canadian cattle industry.

As the company works on growing value through leadership in the sustainable production and processing of ag products (as per its corporate mission statement), Welter says they have emphasized self-sufficiency in growing and acquiring feed, expanding the grazing operation, and ensuring the right blend of cattle at the right time of year.

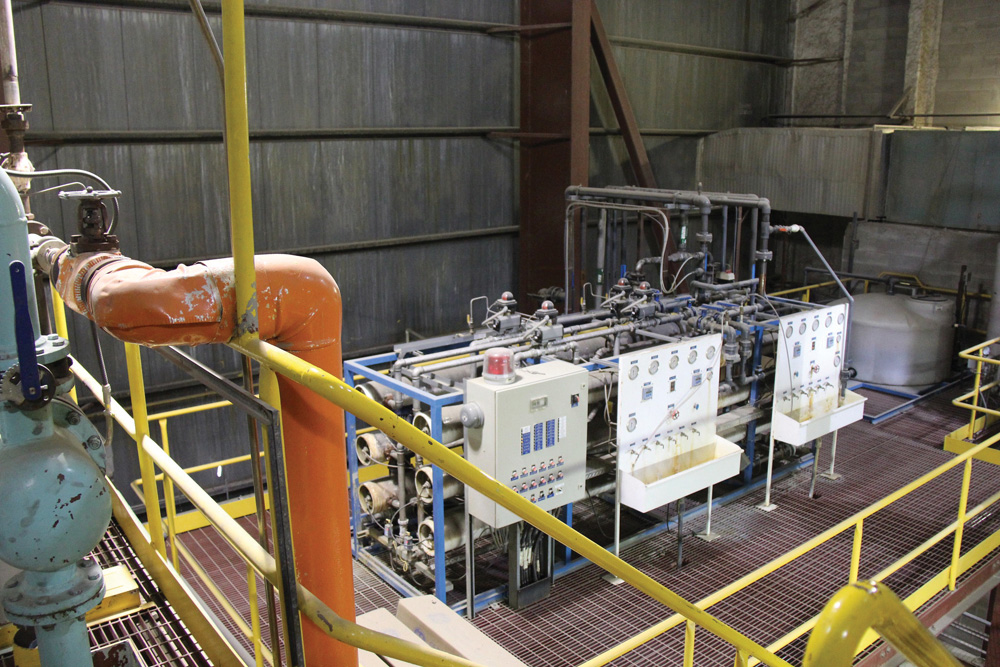

Synergies between the feedlot and ethanol plant can be great with the co-product of wet distillers grain (WDG) used in feedlot rations, and thin stillage added to the water bowls. Ethanol production is a complicated, multi-step process involving acquiring the wheat, milling, cooking, fermentation, distillation — when the WDG is captured — and then further refinement to get to the finished product. As ethanol is a fuel, it is directly affected by the energy sector. The challenges and low prices of oil had a significant impact on the ethanol division at Pound-Maker, and not in a positive way.

Yet, with their experience of making alcohol, Pound-Maker was able to make some changes and produce a grade that can be used for hand sanitizer during the COVID-19 pandemic. This is a moving target and the specifications are tightening up. And as Welter points out, the current level of demand for hand sanitizer is likely going to shrink, but there are opportunities for different grades of alcohol.

“We are looking outside of the cattle business to make the plant profitable,” he says.

The expansion of land to grow 30 per cent of the silage has been one part of the strategy towards sustainability, says Welter. They have also grown the grazing enterprise with 2,000 acres of additional marginal farmland as a way to spread out risk. The intensive grazing operation handles 2,500 head on 4,000 acres of subdivided paddocks. The size of the herds vary depending on the grazing cell. The grass is close to the main lot, which is an important advantage to minimize trucking costs, says Welter.

For the grazing enterprise, they start acquiring 450- to 500-pound cattle in February and lightly background until May 10. They then start going to grass at 650 to 700 pounds. The cattle are coming off grass in late September or early October, having gained about 250 pounds to come back to the lot at 950 pounds. They are then finished out to 1,500 pounds in February and March. They aim for 1.8 lbs./day gain on grass and 3.4 lbs./day gain on the finishing side.

The cattle going directly into the lot are purchased at a wide range of weights, from a number of different venues, including direct from producers and through the auction markets. They start out on a lower-energy backgrounding ration and transition up to the finishing ration.

Pound-Maker is part of the Verified Beef Production Plus (VBP+) program. They have a close relationship with JBS, where 100 per cent of their fat cattle go.

“Being part of the VBP+ has not resulted in changes to our operation, but it does make us more conscientious of what we are doing,” says Welter. “It is a good reminder and monitoring tool.”

Welter adds that VBP+ is the right thing for the beef industry to compete with the other proteins.

The Western Livestock Price Insurance Program (WLPIP) has been important for Pound-Maker and the industry. “It is one more tool to help mitigate risk. It allows us to cover the bottom but still be able to enjoy the upside. Our industry needs to be competitive with the U.S. and the rest of the world,” he says.

On the topic of carbon, Welter thinks there is more to do and learn how it fits with current agricultural practices. There are several ongoing projects that are looking at how to measure the carbon sequestration from various grazing and production methods.

Innovation is also on their strategic horizon. The company is always looking for small things to increase production. Of course, the ethanol plant in the ’90s was seen as extremely innovative at the time.

The company strives to bring value to their shareholders and be strong supporters of the community. Both the shareholders and employees are mostly from the area.

“We will always be involved in community development and support of recreation and leisure activities,” says Welter. “Fifty employees and their families are part of this community and it makes us proud to be part of Pound-Maker.”

The 200-plus shareholders have first right to deliver grain, either wheat for the ethanol plant or barley for the feedlot. Participation in a share-trading program is another option.

The corporate structure is progressive, with the privately traded Pound-Maker Investments encompassing 643,000 shares and owning the two operating companies, Pound-Maker Agventures and Pound-Maker Capital Corp. — the financing entity for customers feeding cattle at Pound-Maker Agventures.

Their community involvement extends further to that of research and extension through the University of Saskatchewan. They work closely with the U of S on different projects whether it be through hosting students or providing cattle for different research trials.

The philosophy of involvement also encompasses the wider industry, through participation and support of producers’ groups such as the Saskatchewan Cattlemen’s Association and the Saskatchewan Cattle Feeders Association.

Pound-Maker’s initial goals — to provide local farmers an alternative market for their grain, to provide employment and to enhance their community — continue to be the guiding force in day-to-day operations. Their impact on the cattle industry in Western Canada has been far-reaching and shows no signs of slowing.

Kelly Sidoryk ranches with her family just west of Lloydminster, Alta. She consults in a number of areas including succession planning and holistic management.