A service expert shows you what to look for to help find some of the more typical problems with used sprayers.

Whether you’re looking at buying a used sprayer or handling maintenance on your own machine, knowing where to look for common problems will speed up the inspection process and help ensure you’re not surprised with a big repair bill later on, along with unexpected downtime. So where do you start looking for trouble?

To find out, Grainews spent some time with Joel Hoehn, regional service manager for Rocky Mountain Equipment in Saskatchewan, walking through one of the company’s used equipment yards looking at some common trouble spots on late-model sprayers.

Using his experience, we pinpoint some typical problem areas producers should keep an eye on.

1. Joints

As he walked around the back of one machine, Joel pointed to the dirt and grease around the edges of a main joint on the boom. When it comes to assessing used machines, sometimes finding dirt is a good thing, he suggests.

“That’s a good indication they actually did maintenance,” he said. “They’re greasy and that stuff doesn’t wash off easily. That’s one thing we always look at. On a sprayer, the best thing to do is walk around with a grease gun. If it takes grease, you know it’s been greased.”

2. Boom ends

Because boom joints are subjected to a lot of stress, especially those near the tips, constant greasing is essential to prolonging their lives. Looking at how this boom folds up suggests the outer joints are in need of repair. If the outside boom ends no longer land properly in their support brackets, they likely have excess play.

“Typically where you have the most wear (on boom joints) is on the breakaways,” said Joel.

3. Leaks

With so much plumbing on a sprayer, it’s important to spend time looking at the fittings for cracks and leaks. Even without any fluid inside them it’s possible to see where chronic leaks have been occurring. There will be indications of drips having dried on the lowest point, like those on these fittings.

“The big thing is the chemical system. With product lines and pumps, you want to make sure there is nothing dripping or leaking,” Joel explains, pointing to places where there are indications product has been persistently dripping over a long period of time.

4. Drain plugs

If the sprayer has been properly winterized, drain plugs will have been removed. It’s important to flush the entire product system with antifreeze at the end of each season and to clean all that out again before operations begin at the start of the next year. Having removable end caps on the booms can really help in getting systems flushed properly and quickly.

“We like to run Spray Guard antifreeze through them (before winter),” he adds. “RV antifreeze can be an acceptable substitute. The big thing guys do wrong is they don’t put enough antifreeze in them. There is still water in the system, so it (antifreeze) gets diluted pretty heavily. It (the freeze point) should be (at least) -30. I suggest putting 10 (five gallon) pails through. With 120-foot booms, there can be a lot of product in there.”

And ensuring the tank water is clean and free of contaminants is not only important for efficacy when spraying, but it’s essential for extending component life.

“Filtered water is huge with these things,” said Joel. “You want to make sure you don’t have dirty water.”

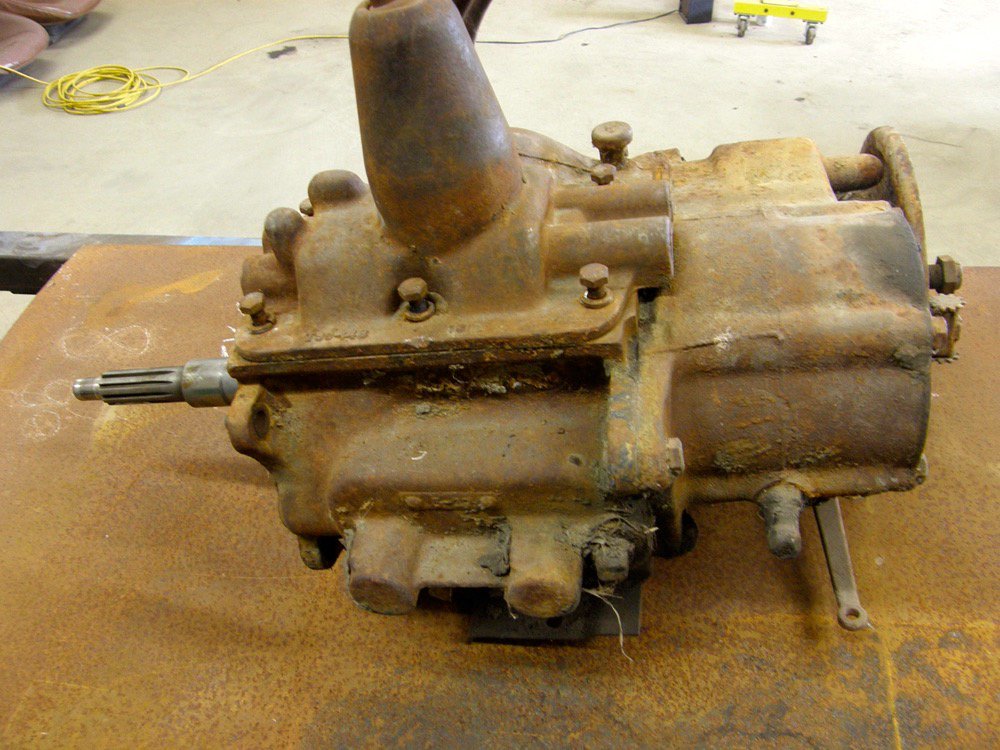

5. Wheel hubs

Joel stops beside a used Case IH machine and points to the wheel hubs, noting annual service is necessary to keep wear on the planetary reduction gears down to a minimum.

“On powered wheels, changing the fluids in them is a big thing,” he explained. “It should be done seasonally with synthetic (oil). I recommend you pop the cover off and look at the gears to see if there are any chips or peeling.”

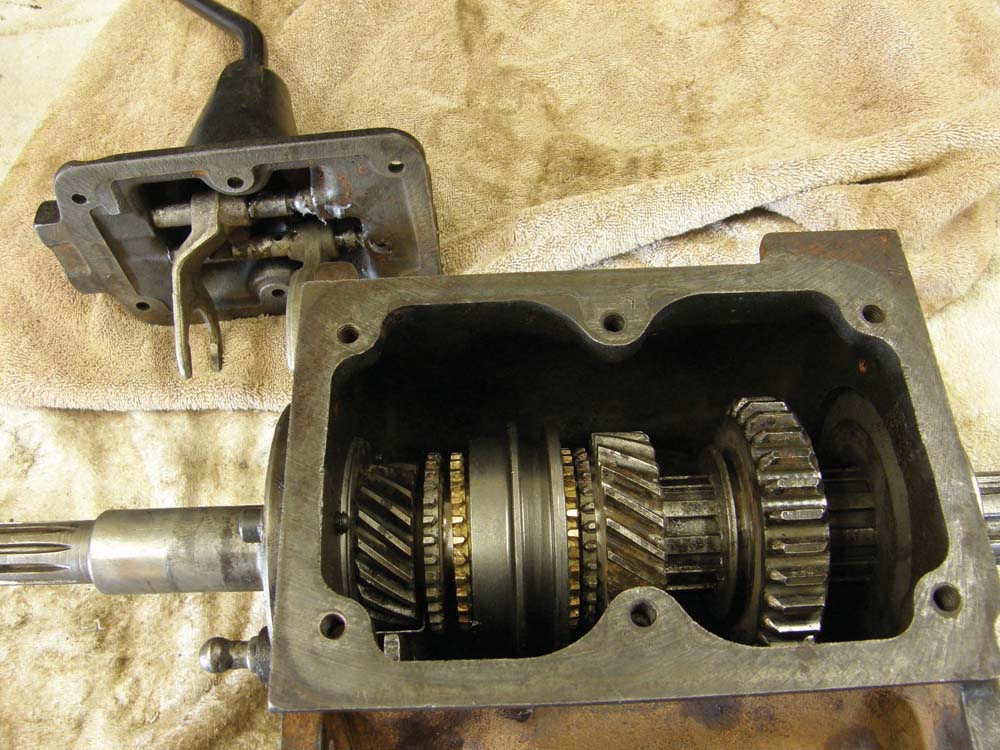

6. Oil

Taking time to inspect the old gear oil after a change in the axle planetaries is important as well. A look at the contaminants in it will be a good indicator of whether the components are wearing normally or if they are facing imminent failure. Under normal circumstances, expect to see swirls of grey in the used oil, just as in this image. But if metal is flaking off bearings or gears, the tiny metal fragments will look like glitter mixed in with the oil.

“Failure looks like kids’ glitter,” said Joel. “That’s peeling hard-surface bearing (material). Normal wear is just grey.”

7. Suspension

Be sure to pay attention to the suspension components on each wheel. The systems on these Case IH models require daily greasing. Check to see if the components are in proper alignment. If the hinged suspension arms appear to be misaligned, there could be excessive play in the joint.

Editor's Note: Grainews would like to thank Joel and the staff at RME for sharing their time and expertise.