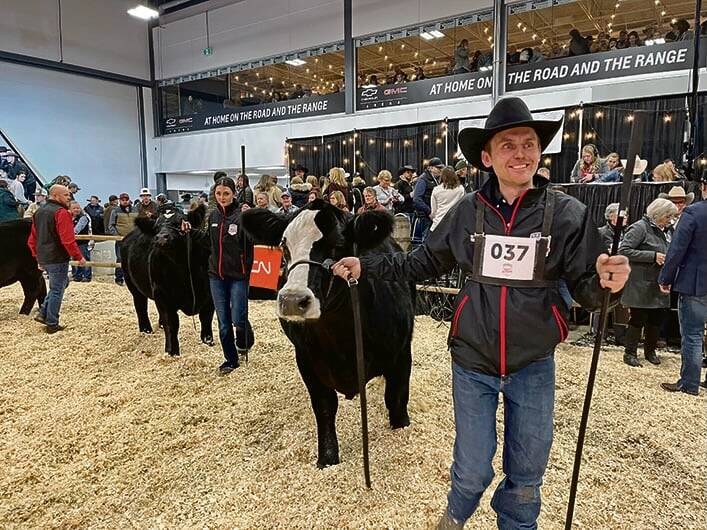

The demos involving cattle are big hits at Ag in Motion, but part of what makes them so successful is the implementation of low-stress cattle handling.

While most of Ag in Motion’s exhibitors focus on the grain side of the industry — machinery, small crop plots — there is a lively livestock area, as well. Here, cowboy hats are common, as well as tech for grazing, electric fencing and watering systems. In the oppressive heat, cattle drink water or lounge in the shade.

Tim Andrew has been coming to Ag in Motion for six years and has been bringing his cattle for just as long. His bulls are used for demonstrations with cattle chute companies.

Read Also

What to know before you go to Agribition 2025

If you’re attending Agribition 2025, this is the place to find out about tickets, dates and what’s happening this year.

Often, he hears from attendees how impressed they are with how quiet his livestock are. Andrew attributes this to how they’re handled.

“These cattle that come to the show, we want them to be very, very responsive to us. So we’ve been training on these bulls for a week,” he says.

Andrew owns and operates Andrew Ranches Limousin, located near Youngstown, Alta. They are primarily a cow-calf and yearling operation where they raise mostly Limousin cattle.

Andrew says showcasing his cattle at Ag in Motion is one of the highlights of his year.

“It is the base of our operation and to be able to present them in front of a large commercial audience like this is just invaluable to us and to the breed,” he says.

But to bring his cattle to Ag in Motion and have them participate in the livestock handling equipment demos, they must be well handled and quiet. People crowd around the equipment as the bulls move through, and young children often want to interact with the animals while they’re resting in their pens.

Andrew incorporates low-stress cattle handling on his operation, which helps with the demeanour of his livestock. He says he got interested in this type of cattle handling after helping his father as a kid.

“Growing up, when we were just running commercial cattle, (my dad) always stressed to the whole family that anytime our cattle are moving any faster than a walk, we’re losing money.”

Low-stress cattle handling

Low-stress cattle handling is a method of handling cattle that keeps stress minimal, both for the animal and for the handler. This keeps them both safer as well as having health benefits and producing easier-to-handle animals.

When it comes to implementing low-stress cattle handling, Andrew says you need to be aware of your stock. In a herd, there are always leaders and followers, he says, and the key is to manage the leaders.

“You’ve got to be able to manage that front cow or else the back ones don’t know where to go,” he says. “So that’s what we’re trying to accomplish there. I mean, anything with her head up looking around, reacting to you a little bit more quickly than the back cattle, they’re going to be your obvious leaders.”

There are many aspects of low-stress cattle handling that Andrew says producers should be aware of, but one of the top ones is the flight zone. The flight zone is the safe, personal space of the cattle, and any entry into this zone will cause a response. Producers need to know when they’ve entered an animal’s flight zone and manage the flight zone.

“And then I’ve got to give some release because if I’m just going to keep pushing, that animal is going to get really agitated, really stressed,” he says.

“Every time you work with that animal, you’re imprinting on them their next opportunity to work with you.”

Andrew says they want the bulls they bring to Ag in Motion to be responsive to handling. Before the show, they work the bulls, four at a time, by moving them through the alley, crowding tub, handling system and the hydraulic squeeze. Once they’ve walked through the handling system, the bulls get some grain, as a reward “for their good work,” says Andrew.

Equipment perspective

Livestock handling equipment has also changed, with human safety and low-stress livestock handling in mind. Equipment manufacturers have become more aware of “designing and laying out equipment for the cattle that lets them use their natural instincts to flow through it,” says Garth Wright, territory technical advisor with Hi-Hog Livestock Handling.

“I know all the manufacturers are trying to make their equipment a little quieter. We’ve always tried to put safety for both handler and livestock as paramount importance.”

Gus Vigier with Tuff Livestock Equipment says a cow’s instinct “is to essentially play follow the leader.” When designing a system, that means making sure the cow can always see the cow in front of her leaving, and making sure they don’t think they’re stuck by themselves, he explains.

“If you can leave them in the group as you’re working on them, give them line of sight, not confine them to the point where they’re completely blind, they seem to really relax and work well with you,” says Vigier.

Wright also sees equipment being designed to make handling livestock easier for both the animal and the person. For example, squeeze chutes have been designed so the animals can pass through easily, and headgates have been created for the comfort of the animal. Producers’ paycheques come from “selling pounds,” he says.

“We’re all trying to do our best to reduce the stress and the loss of those pounds to improve the bottom line and keep everybody healthy and safe raising cattle in this world.”

Vigier says they’re focused on reducing stress of animals as well as the handlers. “Keep it in mind that nobody’s getting younger these days, so we’re trying to get a little bit safer in everything we do.”

That means some specific design choices for Tuff’s Livestock Equipment. “No catwalks, so we don’t have to jump up and down anymore. You can work from the ground,” says Vigier.

Wright says their equipment is based on many of the ideas and designs of Temple Grandin, who has published works about the flight zone and other behaviours of grazing animals.

Details matter in a cattle handling system. For example, Hi-Hog uses sheeted material in its equipment.

“Temple Grandin is a big proponent of the sheeting in terms of comfort for the animal to make them feel a little less stressed to move through,” Wright says. “So, we offer all of our different crowding tubs and our alley designs with sheeted material. Producers have the option to substitute in open bar if they’d like, but sheeting does keep animals and handlers safer.”

According to Grandin’s website, cattle can balk from shadows in the handling system, since they have wide-angle vision. Also seeing people moving through the sides of a chute or moving objects can cause cattle to balk. Sheeted metal reduces the likelihood of that happening.

Wright says he expects to see more technology and research in the future regarding cattle chutes and livestock handling equipment, which will continue to emphasize the importance of animal welfare and the stress of the livestock.

“And our producers are more in tune with improving their own stock skills to reduce stress because everything is based by the pound and they’re starting to realize that when you start using the equipment you’re on the clock, which is the wrong attitude. Slow is fast.”

Vigier echoes the “slow is fast” approach.

“If you’re running after them, they’re going to run away from you. If you can walk and be relaxed, they’re going to have that same mentality when you work with them, so it makes it safer for everybody as you’re working. Take that extra few seconds. It’ll actually make the day go faster because they’ll struggle less.”

Continuous learning

When it comes to low-stress cattle handling, Andrew says it’s important for people to have an open mind. He says sometimes your cattle don’t work the way you’d like them to, or things don’t go according to plan. Even if you’ve been doing it for years, there’s always learning involved.

An example of this is the first day of Ag in Motion when Andrew wasn’t happy with how they worked their cattle. Instead of getting frustrated, Andrew learned from his mistakes and adapted.

“We just put a little grain down in the alleyway. And that troublesome bull, we put him through the Hi-Hog situation today. Because we’d got enough confidence, and he got enough confidence when we only put four bulls into that tub rather than the eight.

“You’ve got to swallow your pride a little and figure out why things are not going right. But there’s such satisfaction when you get that done.”