Glacier FarmMedia – Technology is gaining traction in the beef sector and feedlot operators are turning data into physical and economic gains.

More Ontario feedlot operators are ditching pen and paper in favour of apps, programs and barn tech accessories to track cattle movement and improve management efficiencies.

Why it matters: Tech support and data collection are changing the way feedlots care for animals and helping them remain financially viable when input costs are rising.

Read Also

Unwinding the fibre in feedlot cattle diets

Research into how barley rolling method and undigestible NDF levels affect animal performance and digestive health in finishing diets

When Shauna Soudant, her husband Ron and children Lexi and Jackson took over her father Dave Gardiner’s 2,200 head feedlot operation near Kirkton, they were ready for expansion.

In September 2021, the family welcomed the first load of cattle into their new We Cover facility. The new build provided better ventilation, footing, light, and space for the cattle and less competition at the bunk compared to their older, still-in-use barn.

Designed to meet current and future animal welfare regulations, the new barn and the Soudant’s technology use could be a game-changer.

The Soudants pull cattle from the United States, Ontario and the West. Import requirements involve significant data and paperwork to maintain their restricted status so they use several programs and tools to ensure seamless tracking of all cattle coming and going from their facility.

Ron’s passion and skill lie in cattle nutrition, and as the operation’s feed and general manager, he saw an investment in the Gallagher animal management system as a no-brainer.

His daughter Lexi accessed grants to buy a Gallagher, which scans and traces all animals on arrival and allows for data collection to compare groups and progress. She also secured funding for a Daniels cattle chute to assist with intake.

As part of the Soudants’ restricted status, all animals must be vet-checked, vaccinated within 72 hours of arrival and processed.

“In the past, we have had to delay processing, and our risk has gone way up,” Lexi said. “We’re watching every animal go off the truck and make sure to note anything out of the ordinary when there’s a limper or any of that and recording that and putting them in a hospital pen right away.”

They also use Performance Beef to track feed usage, efficiency, cost and inventory as the cattle move through the barn until they reach optimum weight for shipping.

BovineHub, a weigh scale from Ireland’s StrongBó Agritech in partnership with Dr. Marty Metzger, allows the Soudants to record accurate cattle weights with only the animal’s two front feet on the pad. The information is automatically linked to their RFID tags, creating no-stress tracking for the animal, optimizing diet and increasing profit by allowing for timely cattle marketing.

Use of technology to maintain records, track cattle and data management sets them up to evolve with government mandates in the future, said Ron.

The Van Osch family shared a similar view when they scaled up their operations. They employed Feedlot Health Management Services (FHMS) out of Okotoks, Alta.

Data matters in operations like Van Osch’s, with 11,500 cattle and 10,000 farmed acres focusing on efficiency, sustainability and environmental stewardship to maintain a certified sustainable designation.

Dr. Mac Littlejohn, Van Osch’s FHMS veterinarian, said the system enters all cattle upon arrival and tracks all aspects of their progress.

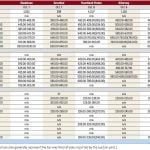

The software produces algorithm charts indicating when an animal will plateau, providing cost savings and efficiency. The second time through the chute, the software will sort the cattle into light, medium and heavy weights and direct them to the appropriate pens.

In addition to feed conversion tracking, Littlejohn receives an automatic alert on his phone when an animal is treated for anything or dies, and all of the latter undergo a post-mortem.

“I had a professor years ago who said, ‘you can’t manage what you don’t measure,’ so everything is essentially measured,” said Littlejohn. “That’s on the crop side, and it’s on the cattle side.”

– Diana Martin is a reporter for Farmtario. Her article originally appeared in the July 25 , 2022 issue.